A guy I found on a chat room Boatdesign.net, T Cubed says: Box masts are easy. Well, conceptually, but not in practice. T Cubed has a lot of good advice. (beow) Pat set up on a solid, level surface = a 2x8 plank, right next to the re-assembled broken mast so he had a full scale model right there. Above are some shots of Pat's work:

T Cubed's work plan: Get your work surface true and straight and draw on them marks to follow when gluing. If you use work horses get a half dozen of them and use wedges and taut string to get it all straight mark the horses (As in the mast needs to go exactly between this mark and that mark on each one).

Draw chalk around each leg so if you nudge one you'll know about it and you'll also know where it should go. Set up on a hard surface.

Don't use fat bulkheads inside the mast as they create 'hard spots' that actually make it weaker and add weight. Minimal bulkheads made of thin stuff is fine.

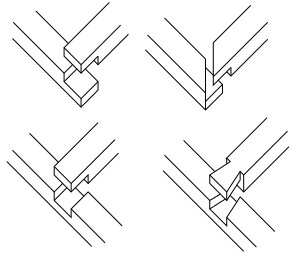

It is very much worthwhile to rabbet each side of front and back planks so the side planks have somewhere to press against when you clamp it all together . Once everything is lubed up with epoxy and you're working against the cure time clock you'll be glad you remembered the 6 P rule.

(6P rule ; proper preparation prevents piss poor performance)

Make a scarph box and scarph up the four planks first into their full lengths. Then work in all the tapers paying close attention to precision. Rabbet crisply where needed. Setup everything. Mark everything. Have twice as many clamps as you think you'll need , even if they're jury rigged clamps. (rope, sticks, wedges) Don't forget lots of plastic shopping bags to place between clamps and glue (plastic bags release well from hardened epoxy).

Do a mock run with your helpers to make sure there are no glitches.

Then glue it all up in one go with slow epoxy. Do a final check by sighting along it that it is indeed true and straight, as you still have a ton more clamps to place and a few more minutes of working time. It should be perfect since you set up the guiding marks with care.

If it ends up with a half inch of (it should not if you did everything right) curve, don't get depressed, it will not make the slightest bit of difference."

|

No comments:

Post a Comment